Scissor jacks are essential tools in your garage, especially when you need a reliable lift for your vehicle. But what happens when your trusty scissor jack starts acting up or fails to function properly?

The frustration is real, and you might be tempted to toss it aside and buy a new one. However, before you do, imagine the satisfaction and savings you’ll experience by repairing it yourself. This not only empowers you with newfound skills but also ensures that your tool is ready whenever you need it.

In this guide, you’ll learn simple, step-by-step methods to get your scissor jack back in working order. Let’s dive into how you can save time and money by tackling this task yourself.

Tools Needed

To fix a scissor jack, you need some simple tools. Safety goggles protect your eyes. A wrench helps turn bolts and nuts. A screwdriver is good for screws. Pliers help grip and twist parts. Lubricant makes moving parts smooth. Rags clean dirt and oil. A flashlight helps you see tiny parts.

Keep these tools nearby while you work. It makes the job easier. Safety first is very important. Always wear your goggles. Use the right tool for each task. This keeps you safe and avoids damage. Start with a clean workspace. This helps you find small parts quickly.

Credit: www.amazon.com

Common Issues

Rust makes the scissor jack weak. It forms when water and air touch metal. Regular cleaning helps stop rust. Use a wire brush to scrub away rust. Apply rust remover for tough spots. Keep your jack dry to avoid corrosion.

Bent parts make the jack unsafe. Heavy loads can bend the metal. Check for any bent pieces often. Use a hammer to gently straighten them. If the damage is big, replace the part. Regular checks prevent accidents.

Screw threads wear out over time. It makes the jack hard to use. Oil the threads to keep them smooth. If the threads are too worn, replace them. New threads ensure the jack works well. Regular maintenance helps the jack last longer.

Safety Precautions

Safety is very important. Always wear gloves to protect your hands. Use goggles to keep your eyes safe. Make sure the jack is on a flat surface. Never use the jack on a slope or hill. Check the jack for any cracks or damage. Replace it if you find any. Keep children away while working. Use only the right tools for repair. Incorrect tools can cause accidents. Always follow the user manual. It has important instructions. Keep a first aid kit nearby. Emergencies can happen anytime. Turn off your car’s engine before starting. This prevents any sudden movements.

Disassembly Process

Start by placing the scissor jack on a flat surface. Make sure it’s stable. Use a wrench to loosen the bolts. Remember to keep the bolts safe. You will need them later. Once bolts are loose, remove the handle. Be careful with the parts. They are small and easy to lose. Next, detach the top plate. Take note of how parts connect. This will help during reassembly. Inspect the gears and screws. Look for damage or wear. Clean the parts using a cloth. Ensure no rust is present. Each part must be clean for smooth operation. Set them aside in order. This helps to remember their positions.

Cleaning And Lubrication

Clean the scissor jack with a soft cloth. Remove any dirt or rust. This keeps the jack working smoothly. Use a brush for hard-to-reach areas. Make sure all parts are clean.

Apply lubricant to the moving parts. Use oil or grease. This helps the jack move easily. Avoid using too much lubricant. It can attract dirt and dust. Check the jack regularly for any sticky spots. Add more lubricant if needed.

Store the jack in a dry place. Keep it away from water. Water can cause rust. Proper care makes the jack last longer.

Credit: www.youtube.com

Repairing Rust Damage

Rust can make a scissor jack weak and unsafe. First, clean the rusty area with a wire brush. This removes loose rust. Then, use sandpaper to make the surface smooth. It’s important to wipe away dust with a clean cloth. Apply a rust remover to the affected spots. Let it sit for a while, then rinse it off. After drying, cover the area with rust-proof paint. This helps protect the metal from future rust. Always make sure the jack is dry before storing it. This prevents new rust from forming.

Fixing Bent Parts

First, check the scissor jack for any bent parts. Use a hammer to gently tap the bent area. Straighten it as much as you can. Avoid hitting too hard, or it might break. Next, use a wrench to adjust the screws. Tighten them to keep the part in place. Make sure everything fits well.

If the part is still bent, try using a vice. Place the bent part in the vice. Slowly tighten the vice until the part is straight. Be careful not to over-tighten. Check the part often to see the progress.

After fixing, test the scissor jack. Ensure it works smoothly. If not, repeat the steps. Always take your time for best results.

Credit: www.walmart.com

Restoring Screw Threads

Clean the screw threads with a brush. Remove all dirt and rust. Use a thread file to fix damaged parts. Align the file with the threads. Move the file back and forth gently. Check the threads often. Make sure they are even and smooth.

Apply some lubricating oil to the threads. The oil helps them move easily. Wipe away extra oil with a cloth. Repeat the process if needed. Always keep the threads clean. They work better that way.

Reassembly Steps

First, gather all the partsof the scissor jack. Check for any missing pieces. Begin by aligning the main frame. Ensure the arms are straight. Next, attach the screwsto secure the arms. Tighten them firmly. The middle pin should be placed correctly. Make sure it moves smoothly. Connect the handle to the main frame. Test the handle movement. It should turn without a hitch. Finally, inspect the entire jack. Look for loose parts or damage. Adjust if needed. Confirm it is ready to use.

Remember, safety first. Always keep fingers away from moving parts. Follow these steps to ensure a safe reassembly.

Testing And Maintenance

Scissor jacks need a safe load test. This checks if they lift well. Put a heavy object on it. Turn the handle slowly. Watch if it lifts the object. Make sure it does not drop fast. If it does, it might be broken. You need to fix it soon. Safety is very important.

Always check the scissor jack for rustand damage. Look at the screws and bolts. Make sure they are tight. If they are loose, tighten them with a wrench. See if the metal has cracks. Cracks can make the jack unsafe. Cleaning the jack helps too. Use a cloth to wipe dust away. A clean jack works better.

Frequently Asked Questions

What Is The Common Problem In A Hydraulic Jack?

A common problem in hydraulic jacks is oil leaks. These leaks can lead to reduced lifting capacity. Regular maintenance and checking seals can prevent this issue. Ensure the hydraulic fluid level is adequate to maintain optimal performance. Addressing leaks promptly extends the lifespan of the jack.

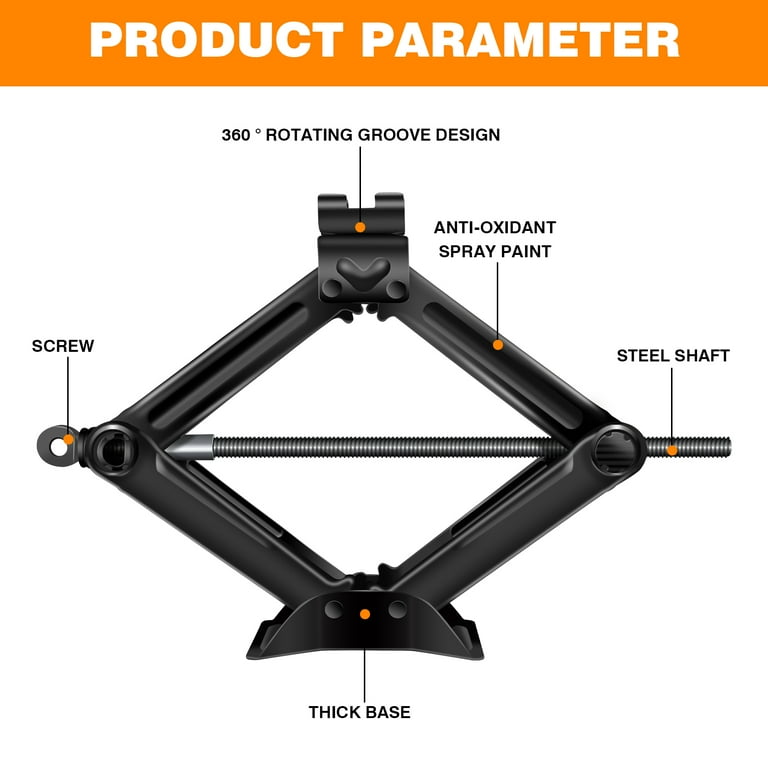

What Are The Parts Of A Scissor Jack?

A scissor jack consists of several key parts: threaded screw, handle, base plate, arms, and support saddle. The threaded screw allows vertical movement, while the arms form the lifting mechanism. The handle provides leverage, and the base plate ensures stability.

The support saddle safely holds the vehicle during lifting.

How To Fix A Jack That Won’t Keep Pressure?

To fix a jack that won’t keep pressure, check for leaks and tighten connections. Replace damaged seals or O-rings. Bleed the jack to remove trapped air. Ensure proper oil levels. Regular maintenance prevents future issues.

Can A Hydraulic Jack Be Repaired?

Yes, you can repair a hydraulic jack. Common fixes include replacing seals, oil, or damaged parts. Regular maintenance helps extend its lifespan. For complex issues, consult a professional to ensure safety and proper function. Always use original parts for replacements to maintain quality and performance.

Conclusion

Repairing a scissor jack can be simple with the right steps. Start by understanding its components. Check for rust or damage. Clean and lubricate moving parts. Replace broken pieces promptly. Test the jack after each repair. Regular maintenance extends its life.

Always prioritize safety during repairs. Use proper tools and wear protective gear. A well-maintained scissor jack ensures safe car lifting. With patience and care, you can fix minor issues yourself. Enjoy the satisfaction of a job well done. Keep your tools ready for future repairs.

Happy repairing!

Hi I am Tamim Hasan, I am a normal person. I like to help people so I want to help you through the blog website. If anyone is benefiting through this blog website then you can help me by sharing comments.