Are you tired of that annoying hissing sound coming from your air hose? An air hose leak can be more than just an irritation; it can affect the efficiency of your tools and even increase your energy bills.

But don’t worry, because you’re about to learn how to fix air hose leaks quickly and easily. In this guide, you’ll discover simple steps to identify leaks, the best materials to seal them, and tips to prevent future issues. Imagine the satisfaction of restoring your equipment to its optimal performance and saving money in the process.

Let’s dive in and empower you with the knowledge to tackle those pesky leaks once and for all.

Identifying Air Hose Leaks

Check the air hose for any cracks or wear. Look closely at the connections and fittings. These spots often leak. Examine the hose surface for damage. Small holes can be hard to see. Shine a flashlight for better view. Sometimes, leaks are near the hose ends.

Listen carefully around the hose. A hissing sound means there’s a leak. Move your ear along the hose. Try to pinpoint the noise. A loud hiss shows a big leak. A soft hiss might be small. Listening helps find hidden leaks.

Mix soap and water in a spray bottle. Spray on the hose parts. Bubbles show where leaks are. Watch the hose as you spray. Bubbles will form around leaks. This method is easy and quick. It’s good for finding small leaks too.

Materials Needed For Repair

Fixing an air hose leak is easy with the right tools. A wrench is important for loosening and tightening parts. Scissors or a knife help cut hoses. Use pliers for gripping and twisting. Don’t forget tape for marking. Have a ruler to measure hose length. Keep these tools handy.

A good repair kit makes work faster. It includes sealant to stop leaks. Also, clamps to hold parts tight. Some kits have patches for big holes. Look for kits with instructions. They help you do the job right.

Sometimes a hose part needs replacement. New fittings can stop leaks. Hose connectors join broken pieces. Having extra hoses is smart. Always check parts fit before buying. This ensures a smooth repair.

Temporary Fixes

Air hose leaks can be quickly patched using tape or clamps. These fixes are temporary but useful for immediate needs. Regular checks can help spot leaks early and prevent bigger issues.

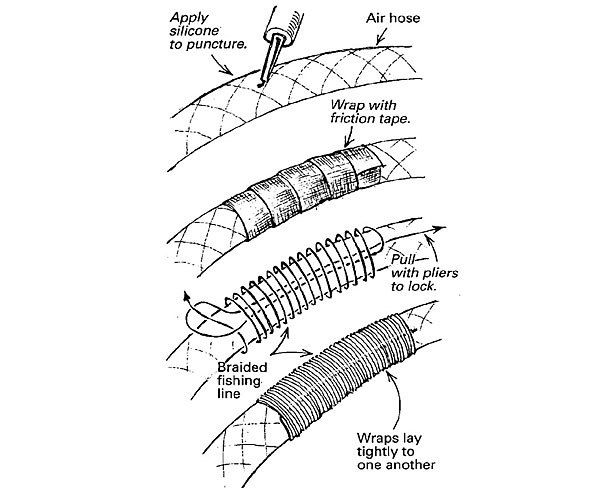

Using Tape

Tape is a quick fix for leaks. Choose a strong, sticky tape. Duct tape works well for this. Wrap the tape around the leak tightly. Make sure no air escapes. Press the tape to seal the hole. This is a temporary solution. You’ll need a better fix later.

Clamps And Bands

Clamps and bands can stop leaks fast. Place a clamp over the hole. Tighten it with a screwdriver. A metal band also works. Slide the band over the leak. Use pliers to tighten the band. These fixes hold until you replace the hose.

Credit: knowhow.napaonline.com

Permanent Repair Solutions

Find the exact leak locationon the air hose. Cut the hose at this spot. Use a sharp bladefor a clean cut. Rejoin the hose with a suitable connector. Make sure it fits tightly. This method stops the air from leaking.

Apply sealantto the leak area. Use a sealant made for air hoses. It should be applied evenly. Let it dry completely. The sealant forms a strong barrier. Air will not escape through the leak.

Identify the damaged sectionof the hose. Remove this section carefully. Replace it with a new piece of hose. Ensure the new section fits well. Use strong clamps for secure fitting. This provides a permanent fix.

Preventing Future Leaks

Check hoses often for signs of wear. Look for cracks or holes. This helps in spotting trouble early. Replace worn hoses quickly. This keeps them safe and strong.

Store hoses in a cool, dry place. Hang them on hooks to avoid kinks. Keep them away from sharp objects. This makes them last longer and stay safe.

Buy hoses made from strong materials. Good hoses resist cracks and breaks. Look for hoses that say durable on the label. Quality hoses save money in the long run.

Credit: www.youtube.com

Safety Precautions

Wearing protective gearkeeps you safe. Use gloves to protect hands. Safety goggles shield eyes. Closed-toe shoes guard feet. Gear protects from flying debris.

Using tools safely is crucial. Keep tools away from children. Hold tools firmly to prevent slips. Always inspecttools before use. Ensure they are not damaged.

Air pressure can be risky. Release pressure slowly to avoid accidents. Check hose for leaks regularly. Avoid touching the hose when pressurized. Stand clear of hose ends.

Credit: www.finehomebuilding.com

Frequently Asked Questions

Can You Fix A Leaking Air Hose?

Yes, you can fix a leaking air hose. First, locate the leak. Clean and dry the area. Use hose repair tape or a hose clamp and rubber patch to seal the leak. Ensure the hose is secure and test for further leaks.

Replace the hose if necessary.

How To Seal A Hole In An Air Hose?

Clean the hose area. Apply a rubber patch or sealant to cover the hole. Secure with adhesive tape. Ensure the patch is fully adhered. Test for leaks by rechecking with air pressure.

How To Seal Air Hose Connections?

To seal air hose connections, use Teflon tape or pipe thread sealant. Wrap tape clockwise around threads. Tighten connections securely with a wrench. Check for leaks by spraying soapy water. Bubbles indicate leaks, which need further tightening. Ensure proper sealing for optimal performance and safety.

What Can I Use To Seal A Leaking Hose?

Use waterproof tape or hose repair kits to seal a leaking hose. Epoxy putty can provide a quick fix. Make sure the hose is dry and clean before application. Replace the hose if damage is extensive. Regular maintenance can prevent future leaks.

Conclusion

Fixing air hose leaks doesn’t have to be hard. Start by finding the leak. Use soapy water to spot bubbles. Then, tighten loose fittings. Replace damaged sections if needed. Always check your tools before use. Regular maintenance prevents future leaks.

Safety comes first, so wear protective gear. Follow these steps for a leak-free hose. You save time and money. Plus, you keep your equipment working well. Remember, a little care goes a long way. Enjoy smooth operations without leaks. Keep your air hoses in top shape.

Happy fixing!

Hi I am Tamim Hasan, I am a normal person. I like to help people so I want to help you through the blog website. If anyone is benefiting through this blog website then you can help me by sharing comments.