If you’ve ever found yourself staring at an engine and wondering how to safely secure it onto a stand, you’re not alone. Whether you’re a seasoned mechanic or just diving into the world of DIY car maintenance, attaching an engine to a stand is a fundamental skill.

It not only ensures your safety but also makes engine work more manageable. Imagine the satisfaction of having a stable engine, ready for your expert attention. This guide will walk you through the process, step-by-step, so you can feel confident and in control.

By the end of this article, you’ll have the knowledge to handle this task with ease, and perhaps even impress yourself along the way. Curious to learn how? Let’s get started.

Choosing The Right Engine Stand

Engine stands come in different types. Folding stands save space. Rotating stands allow easy engine turning. Stationary stands are very strong. Choose what fits your needs best.

Capacity is a key factor. Some stands hold up to 2000 pounds. Others can handle less. Always check the specifications. Make sure it fits your engine size. Stability is vital for safety. Ensure the stand is sturdy enough. Look for strong materials like steel. A good stand can last many years.

Credit: www.youtube.com

Preparing The Workspace

Always wear protective gearlike gloves and goggles. Make sure the area is well-lit. Keep the floor clean and free from clutter. A tidy space helps prevent accidents. Ensure the engine is coolbefore starting. Hot engines can cause burns. Use a buddy system for extra safety.

Gather all required toolsbefore starting. You need a wrench set and a socket set. A hoist or lift will help move the engine. Have a sturdy engine stand ready. Keep a toolboxnearby. This makes tools easy to find. Always check the equipment for any damage. Safe tools are important.

Securing The Engine

Before securing, remove all fluids from the engine. This includes oil and coolant. Use a drain pan to catch the liquids. Make sure all fluids are fully drained. Check twice to ensure nothing is left.

Start by disconnecting the battery. Then, remove all wires and cables. Next, detach the exhaust manifold. Take off the starter and alternator. Keep the parts organized. Label them if necessary. This helps during reassembly. Be gentle to avoid damage.

Credit: www.onallcylinders.com

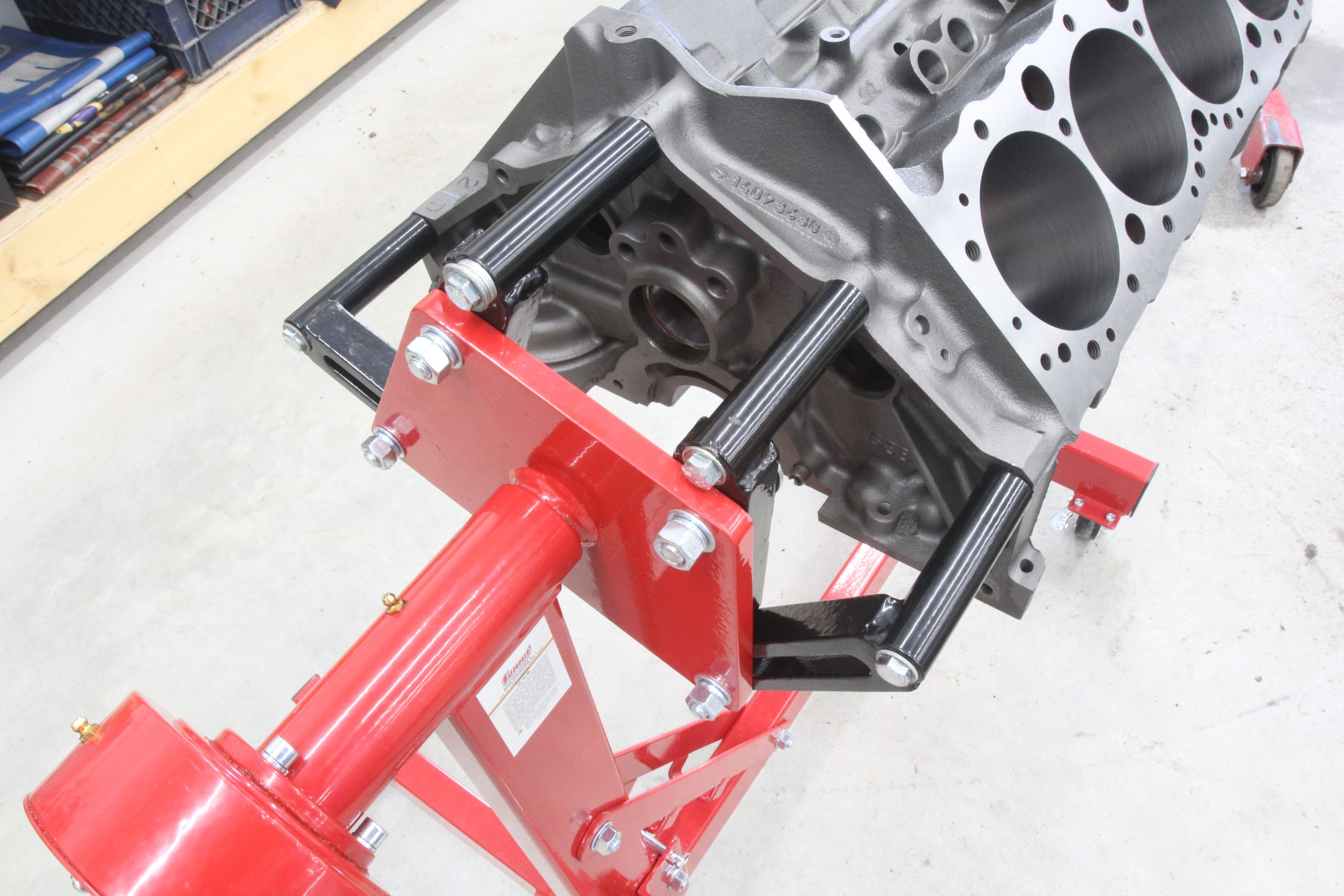

Mounting Brackets And Fixtures

Choosing the right mounting pointsis crucial. Look at the engine carefully. Find spots where it can be held safely. These spots must be strong. Ensure they can support the engine’s weight. Avoid weak parts. Weak parts can break easily. Use bolts or screws if necessary. Always double-check your choices.

Start by placing the bracketson the chosen spots. Use the correct tools. Tighten the brackets securely. Don’t leave them loose. Loose brackets can be dangerous. Check each bracket twice. Make sure they fit well. Test the strength. Give them a gentle push. Ensure they hold steady. Safety first!

Attaching The Engine To The Stand

First, make sure the engine is balanced. Use a level tool to check. The engine must be straight. This helps in avoiding any tilt. Adjust the position if needed. Align all the mounting holes with the stand. This ensures proper fitting. Double-check the alignment to be sure.

Now, take the right-sized bolts. Insert them carefully into the holes. Turn them clockwise to tighten. Use a wrench for more grip. Tighten the bolts evenly and securely. Ensure all bolts are tight. This keeps the engine safe on the stand. Check each bolt twice for safety.

Testing Stability And Balance

Examine the engine’s position on the stand. Look for any wobble. A wobble can cause accidents. Ensure bolts are tight. A loose bolt makes the engine unstable. Try to shake the stand gently. If it moves, adjust it. Fix any loose parts promptly.

Balance is key for engine safety. Check if the engine is leaning. A balanced engine sits evenly. Adjust weights if needed. Add weight to the lighter side. Use a level tool to check balance. Fixing balance prevents tipping. Make sure everything is secure.

Troubleshooting Common Issues

Attaching an engine to a stand can pose challenges, like aligning mounting points correctly. Ensure bolts fit securely to avoid accidents. Double-check the stand’s stability before beginning any work to prevent mishaps.

Bolt Alignment Problems

Bolts must align perfectly with the engine stand holes. Check each bolt to ensure it’s straight. Twisted bolts cause misalignment. Use a wrench to straighten any bent bolt. Measure bolt length if alignment persists. Sometimes, bolts are too long or short. Double-check the engine holes for debris. Clean the holes to remove dirt that blocks alignment. Examine the stand for bent parts. Bent stands affect bolt alignment.

Stand Stability Concerns

Stability is crucial for safe engine handling. Ensure all stand legs touch the ground evenly. Check for loose screws that might affect stability. Tighten any loose screws with a screwdriver. Inspect the stand for any cracks or damage. Replace damaged parts immediately. Balance the engine on the stand carefully. Avoid uneven weight distribution. Uneven weight causes instability. Use a level to confirm the stand is balanced.

Credit: www.streetmusclemag.com

Maintenance Tips For Engine Stand

Attaching an engine to a stand requires careful handling. Begin by aligning the engine mount with the stand’s arms. Secure it tightly using bolts to ensure stability during maintenance. Always double-check for any loose connections to prevent accidents.

Regular Inspections

Always check your engine stand for wear and tear. Make sure all bolts and nuts are tight. Look for any cracks or damage on the stand. A broken stand can be dangerous. Keep an eye on the wheels if your stand has them. They should move smoothly.

Lubrication And Care

Keep your engine stand parts well-lubricated. Use oil or grease on the moving parts. This helps them work better and last longer. Clean the stand often. Dust and dirt can cause problems. Don’t let the stand get rusty. Rust can make it weak.

Frequently Asked Questions

How To Attach An Engine To An Engine Stand?

First, secure the engine on a hoist. Align the engine’s mounting holes with the stand’s arms. Insert bolts through the holes and tighten them securely. Ensure the engine is balanced and stable before releasing the hoist. Double-check all connections for safety.

How To Attach An Engine Support Bar?

To attach an engine support bar, position the bar across the engine bay. Connect hooks to strong points on the engine. Adjust the bar’s height for stability. Ensure the bar is secure and evenly balanced. Double-check all connections for safety.

How Does An Engine Stand Hold An Engine?

An engine stand supports an engine using adjustable arms that securely attach to its mounting points. It provides stability and allows rotation for easy access during repairs or maintenance. This setup ensures the engine remains stationary and safe for the mechanic to work on.

How Can An Engine Be Mounted?

Mount an engine by securing it to the engine bay using mounts. Align mounts with the chassis holes. Insert bolts through mounts and tighten them securely. Ensure proper alignment to avoid vibration. Double-check connections and wiring for safety. Follow manufacturer guidelines for specific engine types and vehicles.

Conclusion

Attaching an engine to a stand is simple with the right steps. Start by ensuring all tools are ready. Next, secure the engine using the stand’s mounts. Check for stability before proceeding. This prevents accidents and keeps your workspace safe.

Remember to double-check all connections. Safety is key, so take your time. Follow the guide and your engine will be attached securely. Enjoy the process and your new skills. Practice makes perfect, and confidence grows with each try. You can now work on your engine with ease.

Keep learning, and happy wrenching!

Hi I am Tamim Hasan, I am a normal person. I like to help people so I want to help you through the blog website. If anyone is benefiting through this blog website then you can help me by sharing comments.